Products

H Series Roughness Measuring Machine

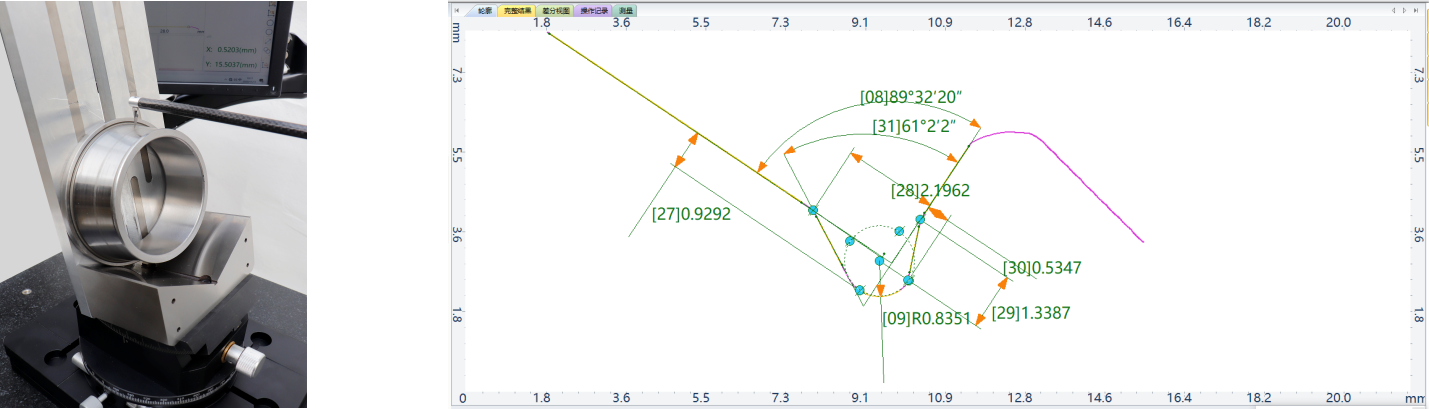

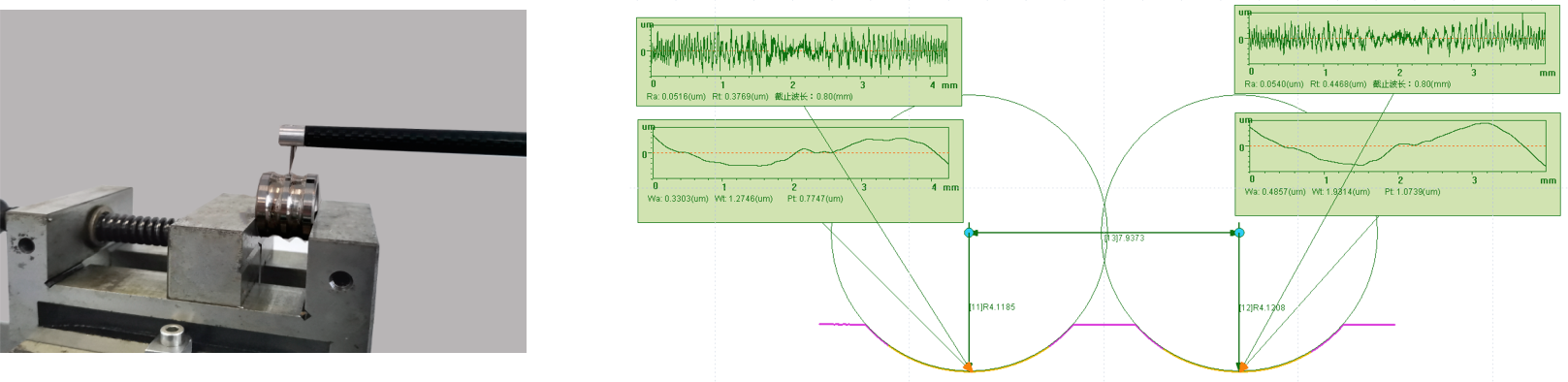

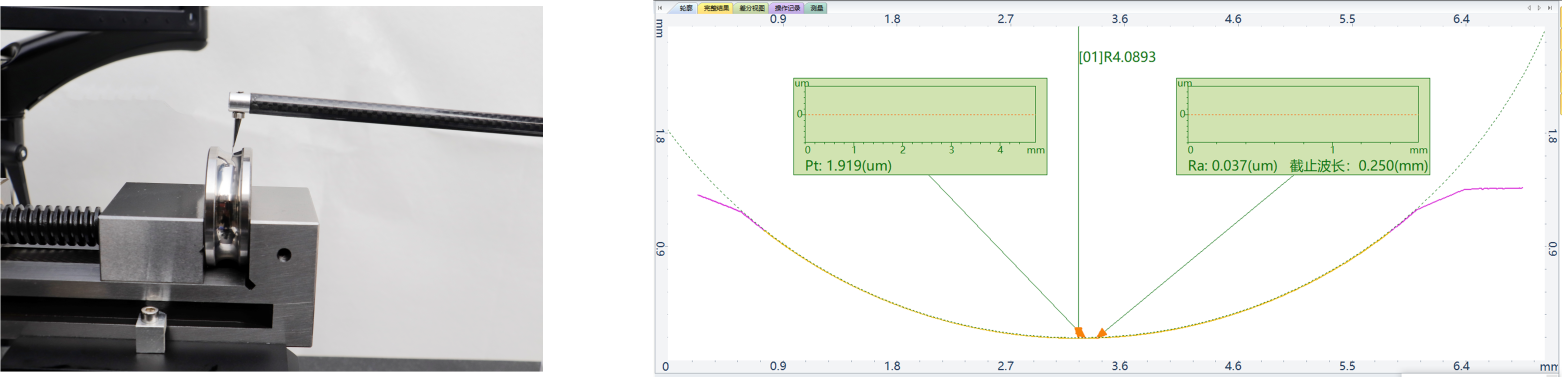

Main Parameter:MMD-H series roughness measuring machine can measure the roughness of a variety of part surfaces, including flat surfaces, beveled surfaces, external cylindrical surfaces, internal bore surfaces, deep groove surfaces, bearing raceways, circular arc surfac

- Product Overview

- Measurement Case

- Download

Roughness Measuring Machine

Surface Roughness Measuring Instrument

Compact Type Flexible Surface Roughness Measuring Machine

Main Functions

It can measure the roughness of a variety of part surfaces, including flat surfaces, beveled surfaces, external cylindrical surfaces, internal bore surfaces, deep groove surfaces, bearing raceways, circular arc surfaces and spherical surfaces, etc., realizing multi-functional precision measurement of surface roughness.

Ra、Rz、Rz(max、Ry)、Rt、Rp、Rpm、Rz(jis)、Rv、R3z、Rsm、Rsk、Rk、Rc、Rpk、Rvk、Mr1、Mr2

Main Features

● High precision: minimum pitch 0.1μm, resolution up to 0.001μm

● 800μm/5mm/20mm large range sensor, high accuracy and repeatability of data with small force measurement

● The natural diamond stylus without guide head can be used in a wide range and more convenient to operate.

● Software can automatically calibrate the accuracy to ensure that the instrument maintains high accuracy online.

Standard Model

Item/Model | MMD-H100 | |

Measuring range | X axis (horizontal) | 100mm |

Z axis(vertical) | 40mm | |

Straightness accuracy | 0.4μm/50mm | |

Sensor resolution | 1nm | |

Cutoff wavelength | 0.25, 0.8, 2.5 | |

Measuring speed | 0.1mm/s, 0.32mm/s, 0.5mm/s, | |

Return speed | 1mm/s (auto) | |

Measurement error | ±5% | |

Measurement stability | 3% | |

Measurement repeatability | 3% | |

Graphical magnification | 10-500000 Auto adjustment | |

Китай прецизионное измерительное оборудование производитель поставщик экспортер Контурографы-профилографы Координатно-измерительные машины контурно-измерительная машина машина для измерения круглости видеоизмерительная система оптическая измерительная система измерение шероховатости, контура и формы

Keywords: roughness and contour measuring instrument,highly precise, simultaneous measurements of surface roughness and form/contour Combined contour and roughness measurements in just one step comes courtesy of proven cutting-edge technology from Wilson metrology large measuring stroke compact universal contour and surface measuring system ENGINE Cylinder Block Bore/ Crank Hole Measuring Machine Cylinder Head Cam/ Guide/ Seat/ Reamer/ Lifter Hole Measuring Machine Engine valve measuring machine Gear housing measuring machine High Accuracy Surface Roughness Contour Measuring Machine High Level Analysis Multiple Function Surface Roughness Contour Measuring Equipment Compact Type Surface Roughness Contour Measuring Instrument Contour and surface roughness measurement in one machine Flexible Manual Control Surface Roughness/Contour Measuring System Precise measurement devices of roughness and contours Contour Measurement Precision Instruments Contour measuring tools & roughness measuring devices Combined contour/roughness measuring systems Surface Contour / Roughness Measuring Machine Portable Surface Finish & Contour Measuring Equipment Form, Contour, & Surface Roughness Measurement Automatic Surface Roughness And Contour Measurement High Level Analysis Multiple Function Surface Roughness Contour Measuring Equipment High-end Extreme Quality Assurance Contour Surface Roughness All-in-One Surface Area Analyzers China vmm cmm Surface roughness tester manufacturers, suppliers & exporters

- Contact us for more parameter information -

| Document Name | File Type | Upload Date | Download |

|---|

-

-  +86 13087559846

+86 13087559846